You may have already chosen your expanded metal mesh product or be planning to purchase expanded metal – but did you know that we offer a range of finishing options that treat the exterior of your metal product by applying a thin layer to its surface for decorative and protective purposes?

Our finishing solutions are suitable for metal mesh products used across a range of applications, including building cladding, internal and external architectural features, fencing, walkways, filters, components and grilles. In this post, we provide more detail on the types of finishing solutions we offer and the ways you may look to use them.

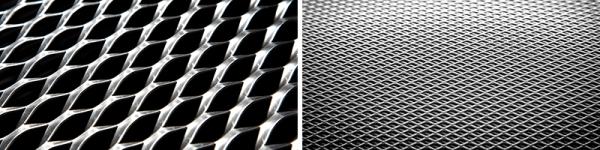

Galvanising, one of the most widely used methods for protecting metal from rusting is achieved in several different ways. The process we use is hot-dip galvanising which involves, as the name implies, dipping the base metal into a molten pool of zinc.

The base metal must first be cleaned either mechanically, chemically, or both to make sure a quality bond can be made between the base metal and the zinc coating. Once cleaned, the base metal is then fluxed to rid it of any residual oxides that might remain after the cleaning process. The base metal is then dipped into a liquid bath of heated zinc and a metallurgical bond is formed.

The advantages of this method are that it is economical; it can be performed quickly and to complex shapes to provide a barrier to weathering and to prevent rusting.

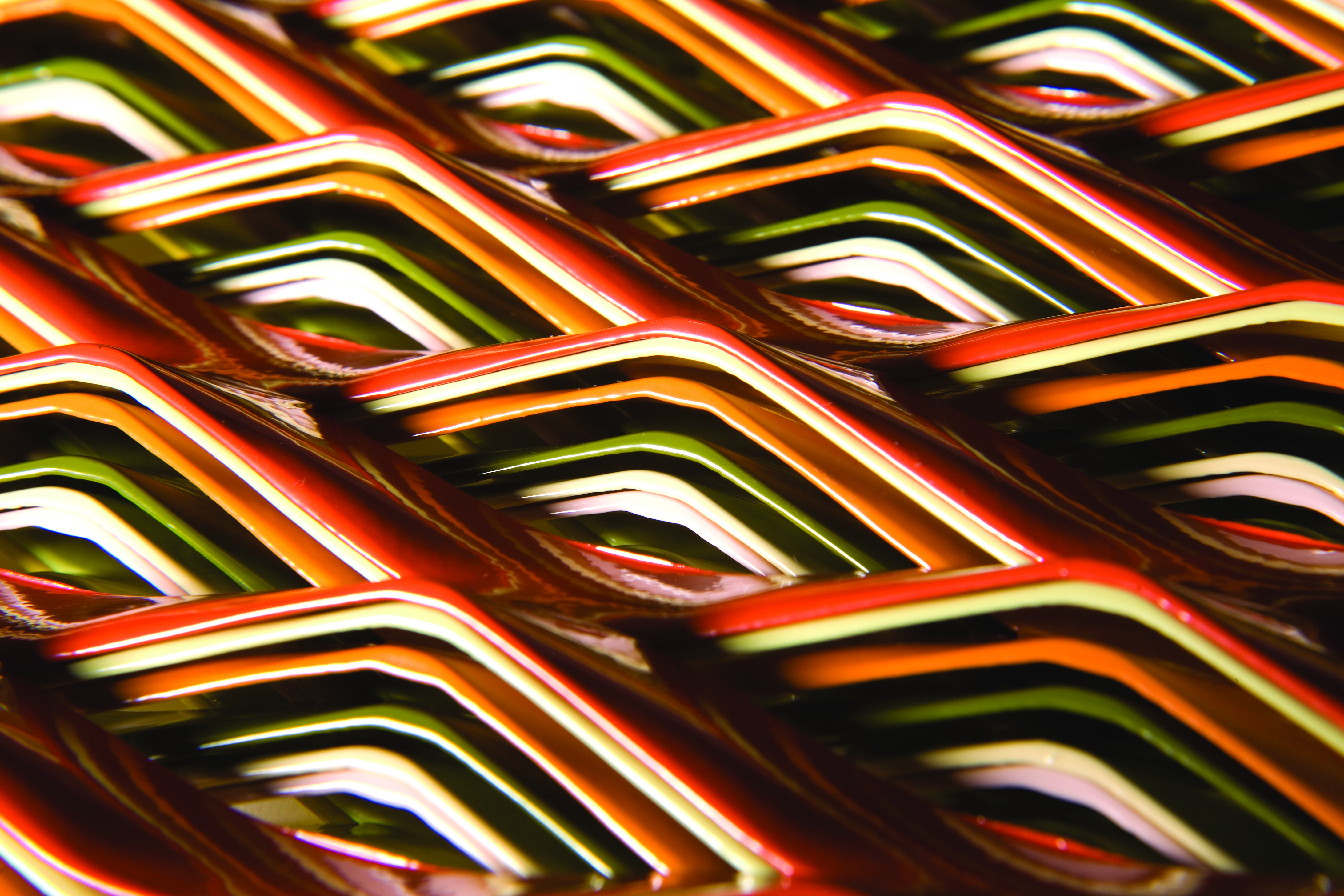

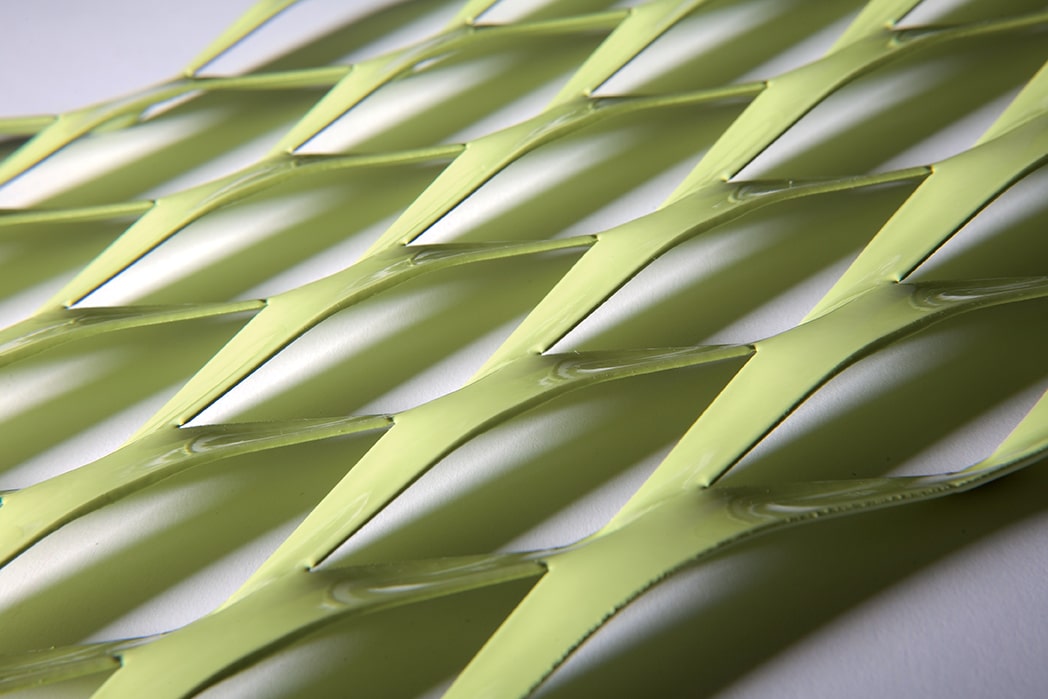

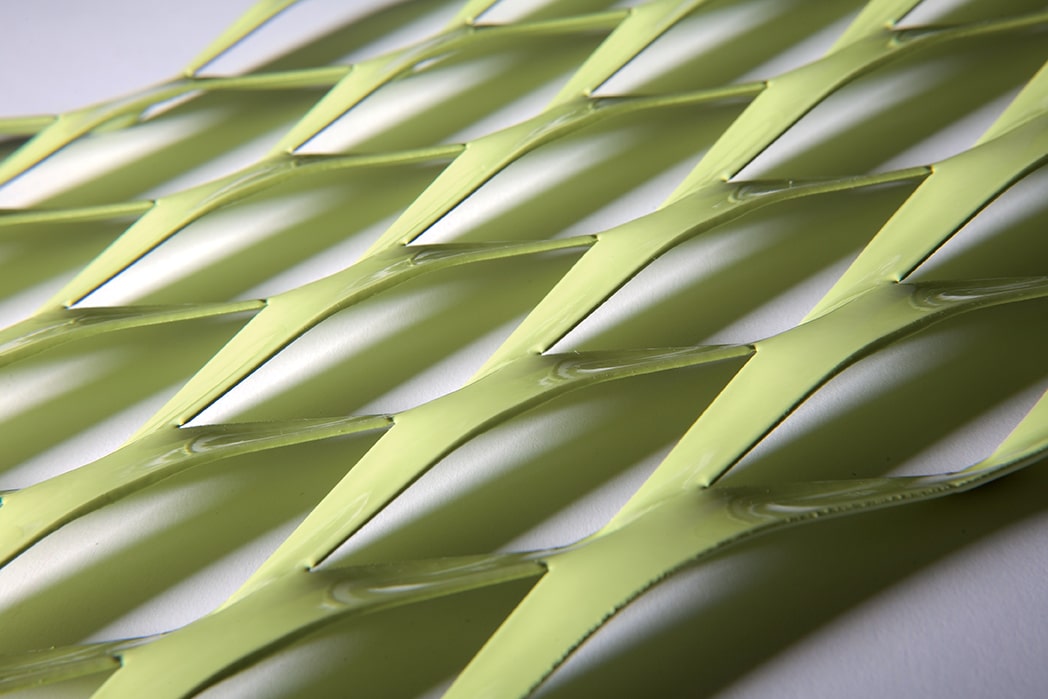

Polyester powder coating offers excellent durability and enables a coloured finish to be applied to our expanded metal mesh range. The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a skin. The powder may be a thermoplastic or a thermoset polymer and is usually used to create a hard finish that is tougher than conventional paint.

Polyester powder coating can be applied to most materials and products within our expanded metal mesh range. It is often used in conjunction with hot-dip galvanising on steel mesh products to provide superior longevity and a smooth, coloured finish.

Anodising is an electrolytic process which is used to produce thick oxide coatings, usually on aluminium and its alloys. Unlike powder coating, which sits on the metal’s surface, anodising permeates the metal’s layers. This provides longevity and a means to maintain natural metallic sheen whilst also introducing a spectacular array of colours, including the renowned Anolok™ range from United Anodisers Limited.

The longevity of the finish really is a fantastic advantage of this method – we know where it has been applied to expanded metal and after 20 years the colour and finish has been as striking as when it was first applied.

We do offer a variety of other specialist coatings for our expanded metal mesh products, contact us to discuss your requirements or take a look at our #meshspotting campaign for some great examples of the types of finishes that can be applied.

To discuss our finishing options for expanded metal mesh products, call our team on +44 (0) 1429 867 388 or email sales@exmesh.co.uk.

GBP

GBP